The Value of Artisanship?

What does it really take to make a handmade piece?

What is it really worth?

In July 2025, we launched a campaign to share our experiences as a new brand founded and managed in Phatthalung, Thailand, along with some questions that we’ve been asking ourselves along the way.

We took one of our signature Banana Fibre bags — handwoven by people we know, where we live and traced its journey from field to final product

Pa’Niat weaving Banana Fibre to make our Toong Gluay Klong bags.

Then we asked our community a simple question:

“How much do you think this bag is worth?”

The answers came in — thoughtful, curious, and often far below the true cost.

We decided to start a conversation by sharing more about what we know.

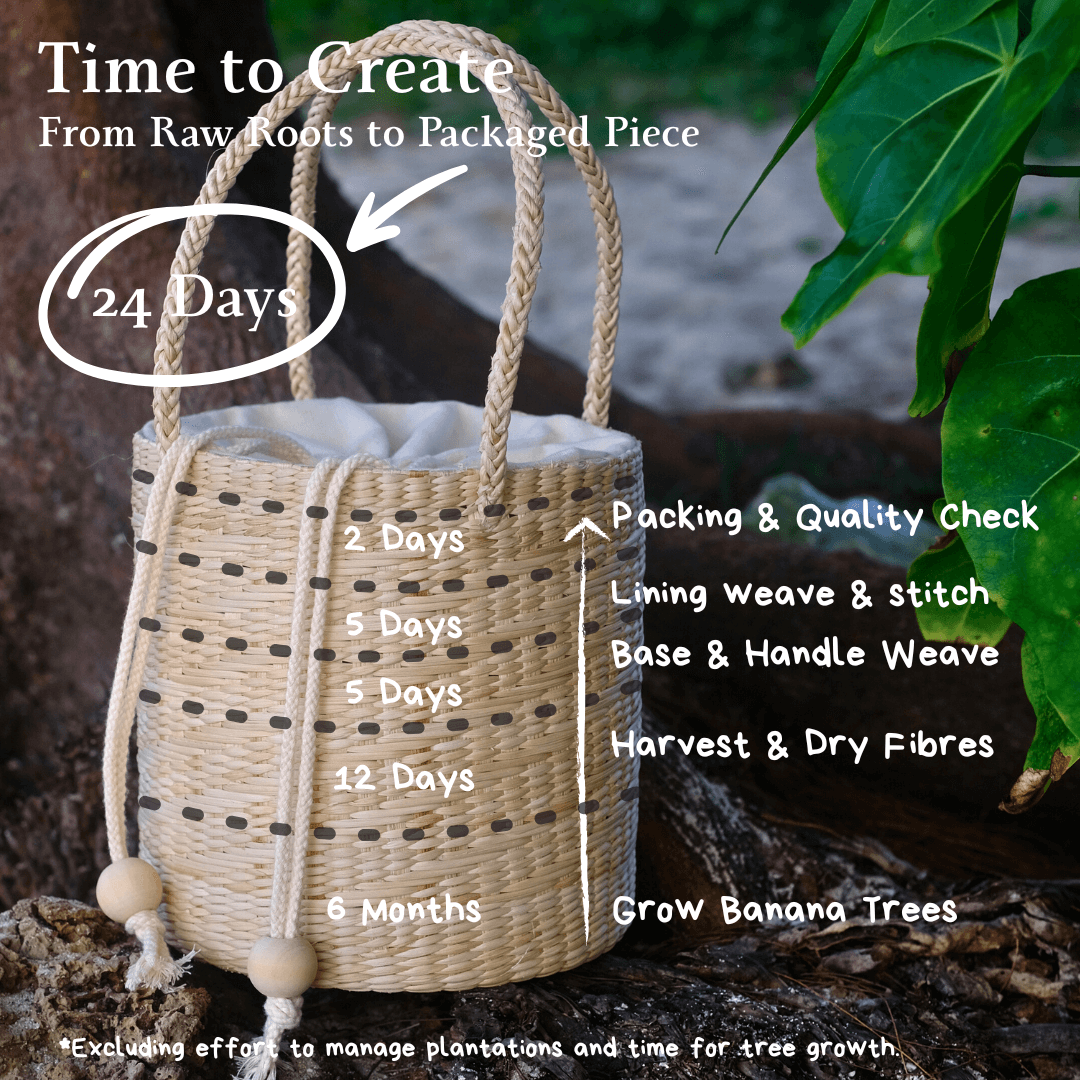

Time Is the First Ingredient.

From raw Banana trees to a finished, stitched, and packed basket, the journey takes 24 days — and that’s not counting the 6+ months it takes to grow the trees.

Drying. Harvesting. Weaving. Stitching. Checking. Packing.

Each step labour intensive.

Each step done by hand.

Each step done with care.

And none of it rushed.

A prototype of the Banana Fibre bag voted for and priced by our followers.

The Hands Behind the Work.

Our pieces aren’t made in factories. They’re made by people we know.

Pa’Ree harvests and dries the Banana fibres.

Pa’Niat weaves the body of the Banana bags.

P’Wit looms the lining that we also use in our Krajood bags.

Na’Yenn stitches it all together.

We are a family business that shares both work and reward.

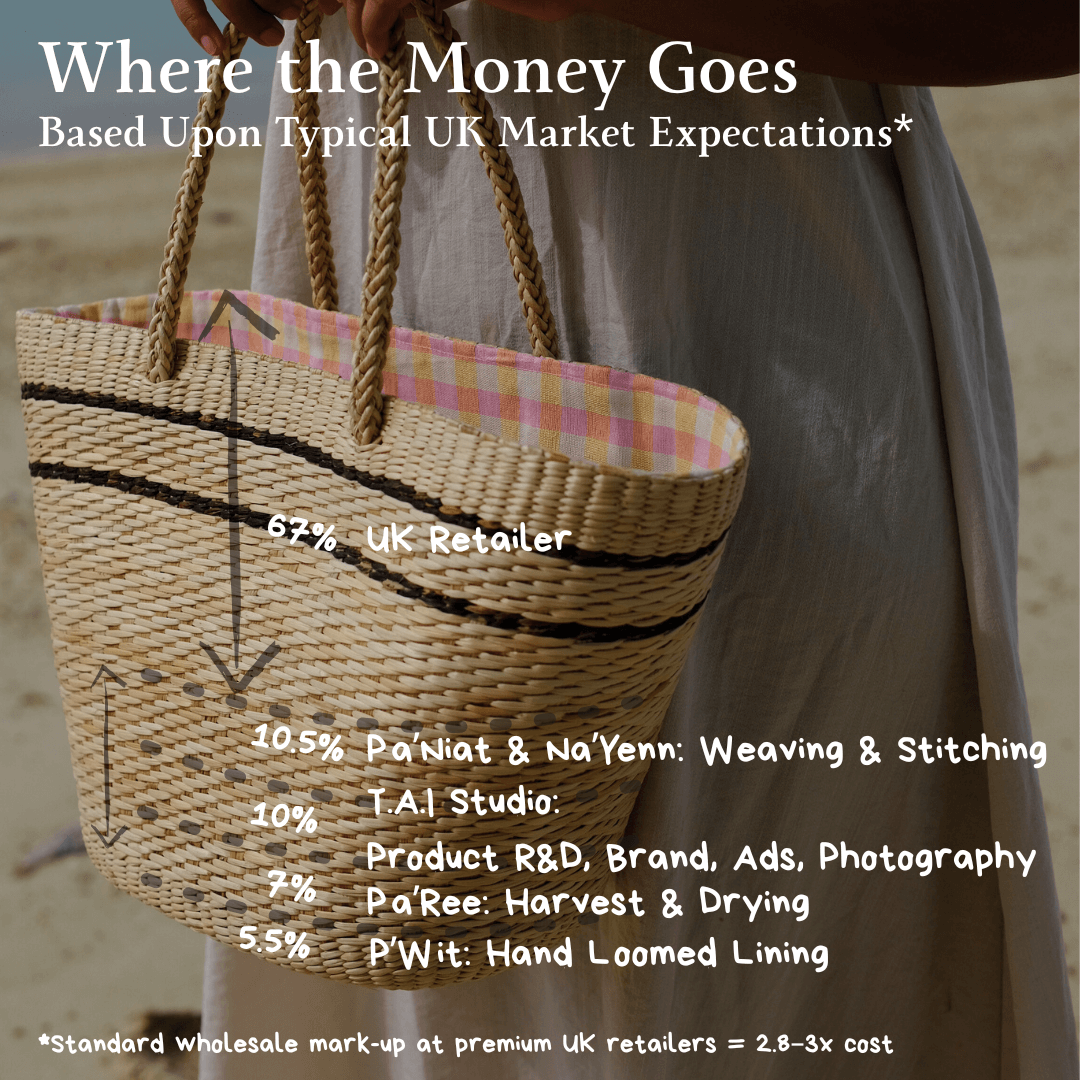

The profit distribution based upon typical UK retailer mark-up expectations.

Who Profits from Artisanal Fashion?

The reality of this model is that retailers take the lion’s share.

In the UK, a premium stockist might mark up the wholesale price by 2.8x–3x.

Which means that for every bag sold:

67% may go to the retailer

Around 6% is shared by each of the makers (in our model)

10% goes to us — to cover everything else

Ethical profit-sharing?

The Hidden Equation.

We calculated the full cost of bringing a single new design to market. From product testing and sample weaving to packaging, insurance, and outreach.

The result?

£50–£120 per piece.

Depending on style, complexity and finishes like hand-embroidery or leather. That figure ignores the investment of time, effort and funding in order to be in the position in the first place.

Economies of scale only come with scale.

How can artisinal-owned brands break through with such a high cost of entry?

How does this sit in the context of a market which celebrates artisanship?

The costs incurred with bringing a Banana Fibre bag to market in the UK.

Back to the Poll. Why Did Most People Guess £40?

Has fashion taught us to forget how things are made?

Is artisan work — especially when made by hand, far from London — still undervalued?

Cost vs Value. The hidden tension.

We want to share what we’re learning, so we can have better conversations.

If a piece is made slowly, with intention…

If it supports a network of real people…

If it carries heritage, not trend…

Should almost 70% of the profit go to the retailer?

Does Western retail pricing support makers — or restrict them?

Is there a disconnect between what we pay and what we think it’s worth?

What do you think?

What do you think?

What’s the balance between ethical pay and profit?

How should we value the heritage & tradition of the makers?

What’s the real value of artisanship?

A Note from T.A.I Studio

This campaign is a reflection of how we work, what we believe, and who we stand with.

—

Shop the Collection

Follow along on Instagram

Want to work together? Contact us here.